Specification

- Material: XPE foam, IXPE foam

- Foaming times: 25 times (40KG/m³), 30 times (33KG/m³)

- Thickness: 50MM, 80MM, 100MM (thickness can be customized)

- Color: black, white (color can be customized)

- Flame retardant grade: UL94 HF-1

Customization

We can provide customized products for all kinds of applications.

Please feel free to contact us if you need.

Tel.: 13824182115

Email: jason.zhan@bofoam.com

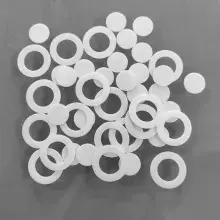

Glass packaging foam insert is a packaging material specially designed to protect fragile items such as glass products. It is mainly made of XPE and other materials, with good cushioning performance and shock-absorbing effect, can effectively reduce the damage caused by vibration, collision and other factors during transportation. In addition, this type of foam also has a certain waterproof and moisture-proof function, which helps to keep the packaged goods dry and clean.

Features

- excellent cushioning: the use of special technology made of foam internal structure of loose, can be very good to absorb the external impact, to provide a full range of protection for vulnerable items.

- lightweight and soft: lightweight and soft texture, will not add extra burden to the goods; at the same time, easy to cut into the required shape and size to adapt to different sizes of products. 3. environmental protection and recycling: most of the foam is recyclable.

- environmentally friendly recyclable: most of the glass packaging foam are recyclable materials, can be recycled after use, reducing environmental pollution.

- chemical corrosion resistance: good resistance to acids and alkalis and other chemicals, even in harsh environments can keep its physical properties unchanged.

- good thermal insulation effect: in addition to the basic protective effect, some types of foam also has a certain thermal insulation performance, suitable for long-distance transportation under the need to control the temperature conditions.

Applications

- home decorations: including a variety of glass vases, mirrors, picture frames and other works of art, need to be especially careful to avoid breakage when handling or mailing.

- electronic products screen: cell phones, tablet PCs and other equipment display screen is very sensitive, the use of special foam package can greatly reduce the risk of damage.

- laboratory equipment: precision laboratory equipment is often expensive and easy to damage, through a reasonable choice of suitable packaging materials to ensure safe delivery of the destination is essential.

- automotive parts: car windows, mirrors and other components also need to be properly protected to ensure that the installation before the intact.

- food and beverage industry: although less direct contact with food, but in some cases (such as the packaging of alcohol products), high-quality foam materials will still be chosen as a liner or filler, both aesthetic and can play a fixed support role.