Specification

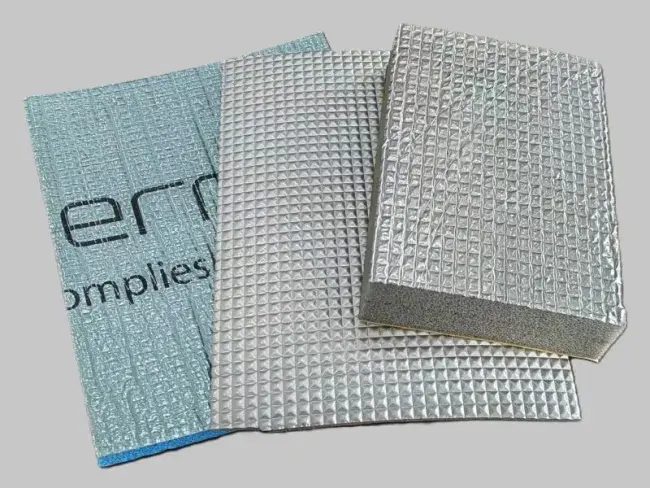

- Surface materials: PE film, Aluminium foil, Non-woven, Flannelette, Leather...

- Base materials: XPE foam, IXPE foam, IXPP foam

Laminated foam is a multifunctional material made by combining two or more foam materials with different properties. This combination can be physically laminated or chemically achieved by fusion between different materials, such as composite aluminium film, fleece, non-woven fabric, leather, PVC, pearl cotton and other materials, can also be made into back adhesive lamination and other ways. According to the different raw materials used, the composite foam material can show a unique combination of properties, such as excellent thermal insulation, sound absorption, cushioning protection ability, etc., widely used in many fields.

Features

- Lightweight: due to its internal structure contains a large number of tiny pores, making the composite foam material has a very low density, light weight.

- Thermal insulation: good closed-cell structure can effectively block the heat transfer, suitable for the need to maintain a stable temperature occasions.

- Sound insulation and noise reduction: the porous structure has a good absorption of sound waves, which can be used to reduce noise pollution.

- Cushioning and anti-shock: soft and elastic properties make it an ideal packaging filler, which can effectively protect fragile items from impact damage.

- Strong weather resistance: some types of composite foam also has a good anti-UV aging performance and waterproof performance, can also be used for a long time in outdoor environments.

- environmental recycling: many new composite foam using more environmentally friendly raw materials, and at the end of the product life cycle can also be recycled.

Application

- Construction industry: as wall insulation materials, roof insulation boards, etc., to improve the energy efficiency of the building;

- Automotive industry: for interior sound insulation, seat padding, and underbody protection;

- Electronic products: providing cushioning packaging solutions for portable devices such as mobile phones and tablet PCs;

- Household products: making mattresses, pillows and other bedding to improve sleep quality;

- Sports and leisure: producing yoga mats, fitness equipment mats, etc. to increase comfort and safety;

- Medical and healthcare: manufacturing wheelchair cushions, surgical bed liners and other assistive devices to reduce patient discomfort.