1. XPE Electronic Foam

- Material Properties

- Closed-cell structure with excellent moisture resistance

- Lightweight and flexible with superior cushioning performance

- Corrosion-resistant with good insulating properties

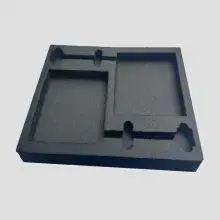

- Applications in Electronics

- Cushioning padding for electronic product packaging

- Thermal insulation layer for lithium battery encapsulation

- Shock protection for electronic components

- Sealing pads for instruments and gauges

- Product Advantages

- Provides reliable cushioning and sealing protection, ensuring electronic product safety during transport and use.

2. IXPE Electronic Foam

- Material Characteristics

- Uniform, fine-cell structure

- Superior anti-static properties

- High resilience and excellent durability

- Applications in the electronics industry

- Anti-static packaging for semiconductor devices

- Transport trays for precision circuit boards

- Shielding pads for electronic equipment

- Protective films for optoelectronic displays

- Product advantages

- Outstanding anti-static and electromagnetic shielding performance, providing comprehensive protection for precision electronic components.

3. IXPP Electronic Foam

- Material Properties

- High rigidity with robust structural support

- High-temperature resistance and dimensional stability

- Superior compression creep resistance

- Low outgassing, contamination-free

- Electronic Industry Applications

- Structural support gaskets for precision instruments

- Buffering components for automated equipment

- Heat dissipation pads for electronic devices

- Heavy-duty electronic equipment packaging

- Product Advantages

- Maintains stable physical properties in high-temperature environments, delivering reliable structural support for electronic equipment.

Bofeng Foam is dedicated to providing high-quality foam material solutions for the electronics industry, ensuring optimal protection for electronic products throughout production, transportation, and usage. Contact us for professional product solutions and technical support.

Email: jason.zhan@bofmat.com