Specification

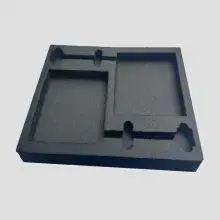

- Long-lasting and stable anti-static performance, large carrying capacity;

- 2, anti-vibration, impact resistance, non-toxic, odorless, moisture, corrosion resistance, high and low temperature resistance;

- 3, Conductive resistance: 10^3~10^6Ω, dissipative resistance: 10^6~10^9Ω;

- 4, Conventional thickness: 3mm, 4mm, 5mm;

- 5, can be designed and produced according to the customer's requirements of size, to achieve the most reasonable use, cost savings.

Customization

We can provide customized products for all kinds of applications.

Please feel free to contact us if you need.

Tel.: 13824182115

Email: jason.zhan@bofoam.com

Anti-static crates are containers specifically designed for storing and transporting electronic components and other products that are sensitive to static electricity. These crates are usually made of conductive or anti-static materials and can effectively prevent damage that may be caused to stored items due to static buildup. It is especially important in the electronics manufacturing industry because many precision electronic components are very sensitive to static electricity, and even a small electrostatic discharge can cause damage.

Features

- anti-static performance: the most central feature is to have a good anti-static effect, can effectively avoid the internal storage by the external environment generated by the impact of static electricity.

- Durability: generally made of high-quality plastic, with good wear resistance and impact resistance, long service life.

- Lightweight and easy to carry: compared with the traditional metal crates, plastic material is more lightweight, easy to handle and carry.

- strong customizability: according to customer demand to provide different size specifications, and support color, pattern and other personalized customization services.

- Environmental protection and energy saving: some products are made of recycled materials, which is in line with the concept of green environmental protection; at the same time, there is no need to consume additional energy for de-static treatment in the process of use.

- High safety: After strict testing and certification to ensure that no harmful substances will be released, harmless to human health.

Application

- electronics manufacturing: such as cell phones, computer motherboards, integrated circuit boards and other high-precision electronic equipment assembly workshop.

- Semiconductor industry: packaging and transportation of ultra-fine microstructure devices such as wafers and chips.

- Precision Instrumentation: Temporary storage of precision parts such as optical lenses and sensors.

- Laboratory research: sample preservation in biomedical experiments.

- Aerospace: safe transit of spacecraft parts such as satellites and rockets.

- Automotive industry: logistics and distribution of key components such as battery packs for electric vehicles and on-board electronic control systems.