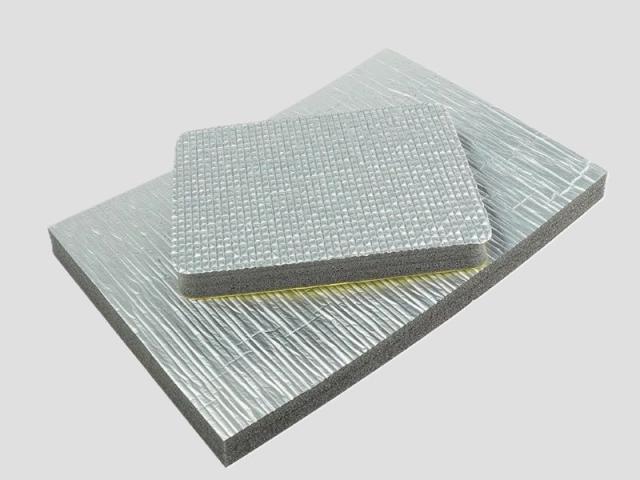

XPE foam insulation has excellent thermal insulation performance and is widely used in many industries such as construction, automobile manufacturing and packaging.

XPE foam insulation features

- Low thermal conductivity

- Definition: Thermal conductivity is an important parameter to measure the thermal conductivity of the material, the lower the value means the better the thermal insulation effect.

- Characteristics: XPE foam has a very low thermal conductivity, usually around 0.03 W / (m-K), much lower than many other common thermal insulation materials.

- Advantage: This means that XPE foam can effectively block heat transfer and provide excellent thermal insulation.

- Closed cell structure

- Definition: Closed cell structure refers to the state in which the bubbles inside the material are independent of each other and are not connected.

- Characteristics: The closed cell structure of XPE foam fills its interior with air, forming an effective thermal barrier.

- Advantage: Reduced heat conduction: The closed cell structure reduces the conduction path of heat through the interior of the material. Waterproof and moisture resistant: the closed cell structure also prevents moisture penetration, keeping the material dry and insulating.

- Lightweight and High Strength

- Definition: Lightweight and high-strength means that the material is lighter in weight while maintaining high strength.

- Characteristics: XPE foam has low density but good mechanical strength and durability.

- Advantage: Easy to install: The lightweight feature makes XPE foam easy to handle and install. Structural stability: the high strength characteristics ensure the stability and reliability of the material in the process of use.

- Wide range of temperature resistance

- Definition: Temperature range refers to the ability of the material to work normally in a certain temperature range.

- Characteristics: XPE foam can maintain its performance in a wide range of temperatures, usually can be used between -40 ° C to +70 ° C. The material can be used in a wide range of temperatures.

- Advantages: Adaptability: Suitable for a wide range of environmental conditions, including cold regions and high temperatures. Long service life: maintains long service life even under extreme temperature conditions.

- Environmentally friendly and non-toxic

- Definition: Environmentally friendly and non-toxic means that the material is harmless to the environment and human body.

- Characteristics: XPE foam is a non-toxic and harmless material that does not contain any harmful chemicals.

- Advantages: Safe and reliable: friendly to human body and environment, suitable for various application scenarios. Easy to recycle: can be recycled and reused after disposal, reducing environmental pollution.

XPE foam insulation application examples

- Construction industry: as wall insulation, roof waterproofing and thermal insulation materials, etc., to effectively improve the energy efficiency of buildings.

- automotive industry: used to make vehicle interior sound insulation and heat insulation pads, enhance the comfort of driving.

- Packaging materials: Protect fragile items from impact damage while providing temperature control.

- Sporting goods: such as pontoon boards, yoga mats, etc., to take advantage of its softness and elasticity.

- Other fields: such as agricultural greenhouse covering materials, medical rehabilitation equipment padding, etc.