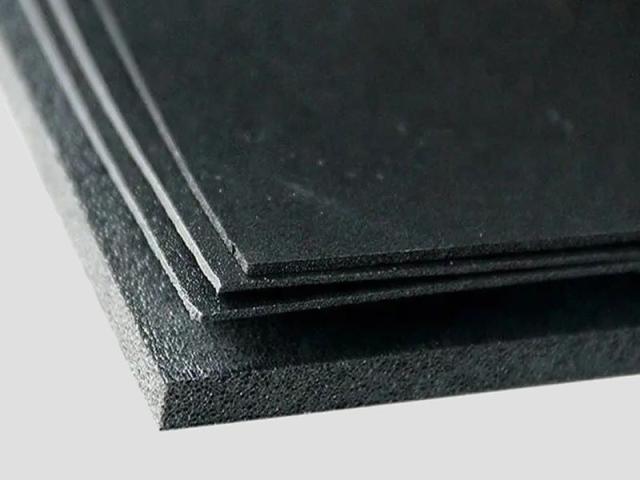

PE foam, known as Polyethylene Foam (Polyethylene Foam), is a lightweight material made from low-density polyethylene through the foaming process. It has good cushioning properties, thermal insulation and sound absorption, and has a wide range of applications in packaging, construction, automobile manufacturing and many other fields.

Features of PE foam

- Lightweight: due to its internal structure contains a large number of bubbles, making PE foam is much lighter than the same volume of solid materials.

- Strong cushioning protection: can effectively absorb the impact, to provide excellent protection for the packaged goods. 3.

- waterproof and moisture-proof: does not absorb water, even in a humid environment can maintain the original form and function.

- chemical corrosion resistance: good resistance to most acid and alkali solutions.

- Environmentally friendly and recyclable: the raw materials used in the production process are relatively environmentally friendly and can be recycled in a specific way after disposal.

- Easy to process molding: can be cut into different shapes and sizes according to the needs of the product, easy to use.

PE foam applications

- Packaging industry

- Packaging of electronic products: such as cell phones, computers and other precision instruments external packaging, the use of its excellent cushioning properties to prevent damage during transportation.

- Fragile protection: glass products, ceramic ware and other fragile items lined with filler.

- Food preservation: some types of PE foam can also be used as food-grade packaging materials to help extend the shelf life of food.

- Construction field

- Laying under the floor: used as sound insulation layer or heat preservation layer.

- Roof insulation: placed between the roof and tiles to enhance the overall heat insulation effect of the house.

- Pipe insulation: wrapped around the outside of water pipes to reduce heat loss and prevent condensation.

- Automobile Manufacturing

- Interior parts production: seat cushion, door panel lining and other parts are made of PE foam, which improves riding comfort and reduces the weight of the car body at the same time.

- Engine compartment sound insulation: installed in the area around the engine to reduce the degree of noise transmission to the cabin.

- Other aspects

- Sporting goods: make yoga mats, swimming floats and other fitness equipment.

- Crafts and Gifts: used as decorative materials or basic supports for handicrafts.

- Medical and health care: some medical equipment packaging materials will also choose PE foam.