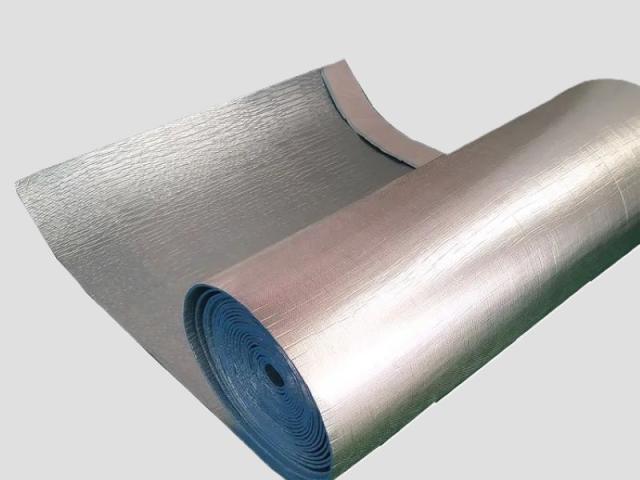

Aluminum foil thermal insulation foam is a multifunctional composite material made of highly efficient thermal insulation material (such as XPE, etc.) as the substrate, with one or more layers of aluminum foil compounded on the surface. It combines the reflective properties of aluminum foil and the thermal insulation properties of the substrate, which can effectively reduce heat conduction, heat convection and heat radiation, and is widely used in construction, industrial equipment, transportation and other fields.

The main function of aluminum foil thermal insulation foam is to realize the heat insulation effect by reflecting heat radiation and reducing heat transfer, and at the same time, it has a variety of additional functions such as moisture-proof, sound insulation, fire prevention and so on, which is a kind of new material with high efficiency and energy-saving.

Features of aluminum foil thermal insulation foam

- Efficient heat preservation and insulation performance: Aluminum foil has a very high thermal reflectivity (up to 95%-97%), which can effectively reflect thermal radiation and reduce heat transfer. The substrate itself has a low thermal conductivity, which can effectively block heat conduction and heat convection, and further enhance the overall thermal insulation effect.

- Excellent moisture-proof performance: the dense surface of aluminum foil can effectively prevent water vapor infiltration, preventing the insulation material from moisture and reduce performance. It is especially suitable for humid environments or scenarios that require moisture protection. 3.

- Lightweight and easy to install: Aluminum foil thermal insulation foam is lightweight, flexible, easy to cut and install, suitable for a variety of complex shapes of construction needs. The installation process does not require special tools, convenient construction, saving labor costs. 4.

- good fire performance: according to the different substrates, aluminum foil thermal insulation foam can choose flame retardant materials, has a certain fire resistance, in line with fire safety requirements.

- Environmental protection and energy saving: the material can be recycled, environmental performance is superior. In the use of the process can significantly reduce energy consumption, in line with the requirements of green building and energy saving and emission reduction.

- Multifunctionality: In addition to thermal insulation, it also has the functions of sound insulation, shock absorption, anti-corrosion, etc., to meet a variety of needs.

Application of Aluminum Foil Thermal Insulation Foam

- Construction field

- Roof and wall insulation: used for roof and wall insulation of houses, factories, warehouses and other buildings to reduce heat radiation in summer and heat loss in winter.

- Floor and underfloor heating system: laid under the floor as a thermal insulation layer to improve the thermal efficiency of the underfloor heating system.

- Pipe insulation: used for heat insulation of hot water pipes, cold water pipes and ventilation pipes in buildings to prevent energy loss and condensation.

- Industrial field

- Industrial equipment thermal insulation: widely used in boilers, reaction kettles, storage tanks and other high-temperature equipment thermal insulation to improve energy utilization.

- Air-conditioning and refrigeration system: It is used for heat insulation of air-conditioning ducts, cold storage, refrigerated trucks, etc. to ensure temperature stability.

- Pipe insulation: used in petroleum, chemical, electric power and other industries for pipeline insulation for conveying high or low temperature media.

- Transportation field

- Automobile heat insulation: used in automobile roof, floor, engine compartment and other parts of the heat insulation and noise reduction, to enhance the comfort of the car.

- Cold storage transportation: It is used for heat insulation of refrigerated trucks and cold chain transportation equipment to ensure the temperature stability of the goods during transportation.

- Other fields

- Agricultural greenhouse: Used in greenhouses for heat preservation and insulation, regulating the indoor temperature and promoting the growth of crops.

- Outdoor equipment: used for heat insulation of tents, sleeping bags and other outdoor products to enhance the experience.